Our Processes

Our Conformity to Industry Standard

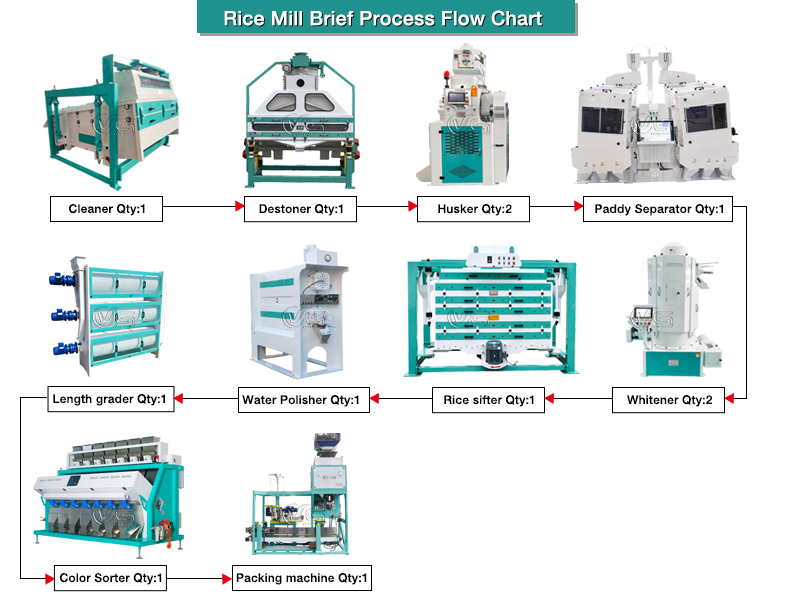

The Image Below briefly describes the normal ISO 9001:2015 Certified (which we are accredited as certified for ) preparation process for Quality Rice Milling

Quality Rice Milling Process

Here at Tana Group LTD, We follow the ISO certifications on the correct procedures that need to be undertaken to ensure conformity to industry standards. To make sure we produce the best quality rice, we use the elaborate rice processing steps below.

1. Paddy Dryer

2. Paddy Cleaner

3. De Stoaner

4. De Husker

5. Separator

6. Polisher

7. Grader

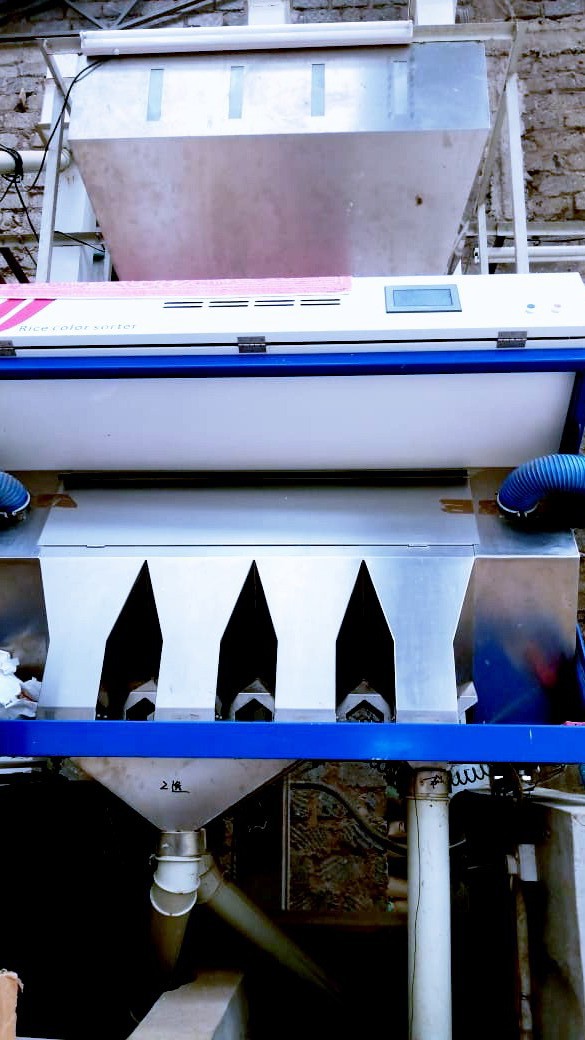

8. Colour Sorter